FSP Hydro PTM 750W: review and tests. Mining test

Overview: FSP Hydro PTM 750W (Mining / Gaming)

The Hydro PTM series is a fully modular design that comes in three different configurations, 550W, 650W, and 750W. As we can see by the icons displayed across the front of the box.

The Hydro PTM is not only ready for Intel’s latest and greatest CPU but their also VR ready! FSP must be really proud of the Hydro PTM seeing that they’ve also given it a 10-year warranty, included 100% Japan-made E-cap’s, offers OdB Zero Noise, and is rated for 80PLUS Platinum. With all that being said, we must be looking at a top contender for the 750W range.

Turning the box around we are greeted with more in-depth information. Here are the main features listed for the Hydro PTM.

- Unique product ID with changeable side stickers for DIY enthusiasts and gamers.

- Complies with newest ATX12 v2.4 & EPS12 v2.92 standards.

- High Efficiency ≥ 92%.

- Active PFC ≥ 99%.

- 80PLUS Platinum Certification.

- Powerful +12V single rail design.

- Advanced full modular design with ribbon cables.

- Full Japan-made electrolytic capacitors.

- Support 6+2 pin PCI-Express Connectors.

- Quiet and Long-Lasting 135mm FDB fan.

- Complete Protections: OCP, OVP, SCP, OPP, UVP, OTP.

- Global Safety Approved.

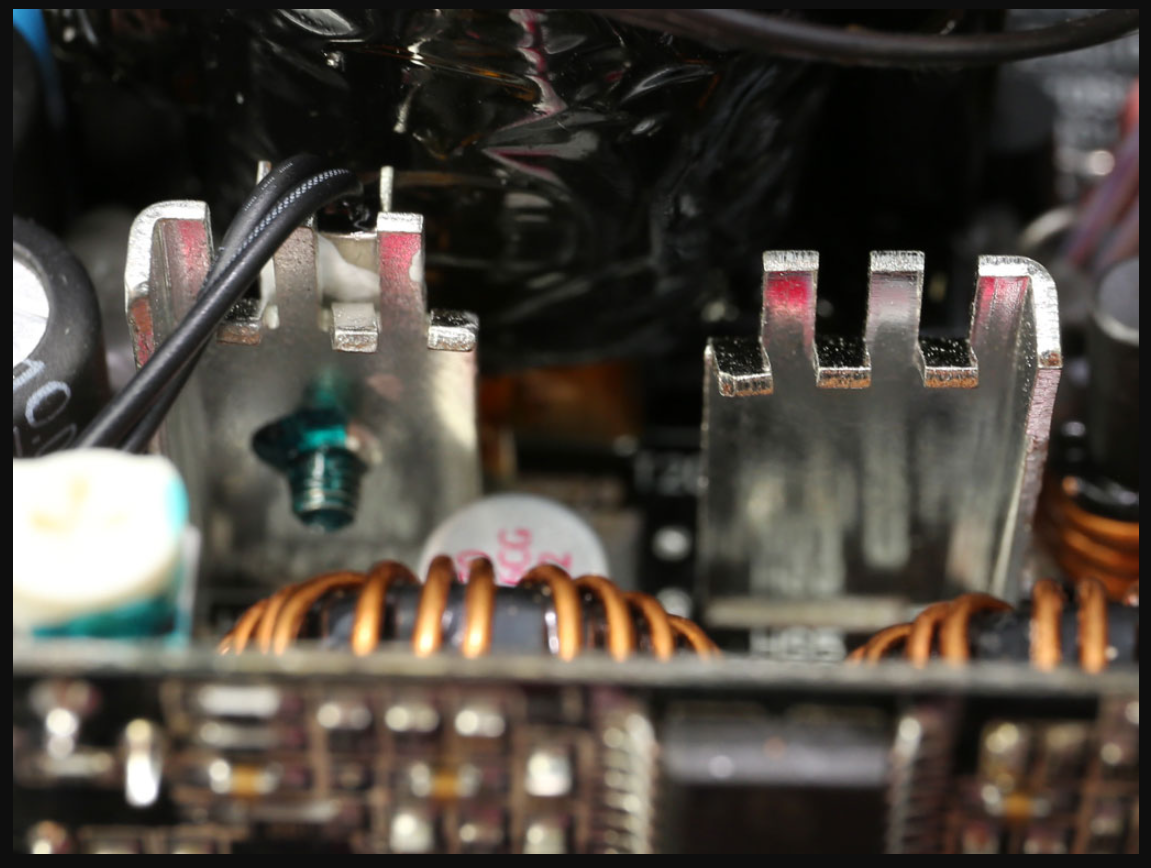

FSP has added in a few extras such as the special heatsink designed for the 12v switching circuit. They’ve also implemented a server grade bus bar design for connecting the daughter board to the main board to minimize any power loss pushing for even more efficiency.

Pair all that with a nice DC-DC design and some tight voltage regulation, the Hydro PTM, by all means, should produce some nice testing results. We’ll just have to see if it sinks or swims.

Along the side, we have their power specs listed.

|

Hydro PTM 750W – DC Output |

|||||

|

DC Output |

+3.3V |

+5V |

+12V |

-12V |

+5VSB |

|

20A |

20A |

62.5A |

0.3A |

2.5A |

|

|

Max Power @ 50°C |

120W |

750W |

3.6W |

12.5W |

|

|

750W |

|||||

As stated earlier, we have a single +12V rail rated for 62.5A, with the two minor rails rated for 20A each.

The Hydro PTM utilizes an intelligent fan speed control circuit designed with a 135mm FDB (Fluid Dynamic Bearing) to provide low noise and reliable operation at low to medium loads. As we can see by the above graph, we should run 700+/- RPM up until 60% (roughly 450W) and then ramp up to a little over 1200+/- RPM at full load.

With the Hydro PTM being rated for 80PLUS Platinum, we expect to see efficiency numbers to be at least 90% @ 20% load, 92% @ 50% load, and 89% @ 100% load. Of course, we won’t complain if they’re better than that, will we?

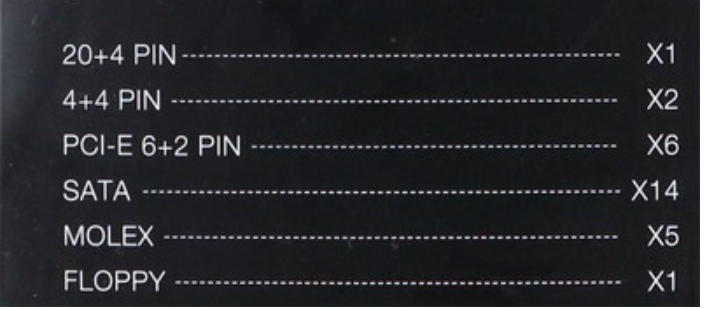

FSP even gives you a basic cable and connector layout. All the information one would need to have if shopping for a unit in a retail store.

Opening up the box, we are greeted with a nicely packed PSU. Included in the smaller box are the modular ribbon cables and the power cord. Next, we have a sleeve containing the two extra stickers options should you want to change the color from blue to red or green. Lastly, we have a pamphlet and a single piece of paper folded up several times acting as a user manual.

Taking a good look at the Hydro PTM 750W, we can see that everything fits nicely and gives it an overall good look.

When purchasing a high-quality unit, the consumer is definitely going to want to see that reflected in the looks of the product. Even though it’s going to get tucked away inside a computer case.

Looking at the rear of the unit, I do like the look of the vents when compared to the standard. With the rounded slot design, hopefully, it doesn’t create any extra acoustics during operation.

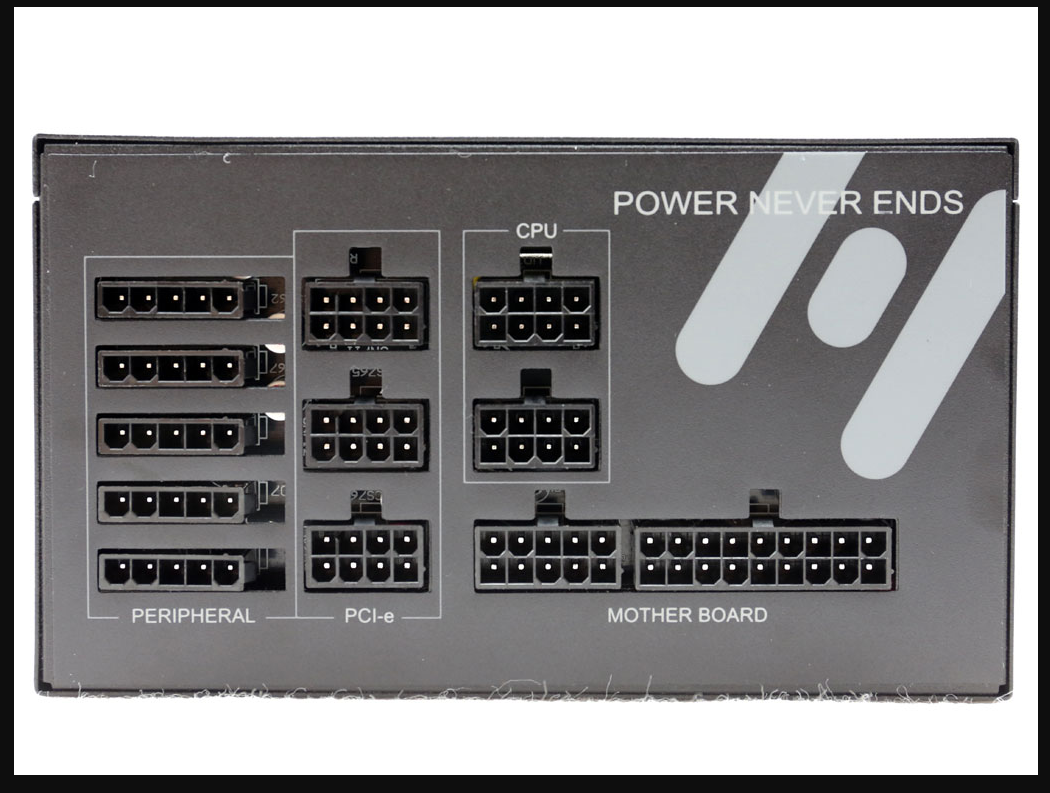

The modular interface section looks nice and clean. I’m not one for the 5×1 peripheral connector. I know they save space and all, but they just don’t seem to fit as tight as a standard 2×3 connector does.

On the side of the casing, The Hydro PTM 750W comes with blue stickers installed, and there’s a pamphlet that has a set of green and a set of red stickers if you would like to match it to your PC Cases color scheme.

Looking at the fan grille, I’m to sure about the design as well as the bling goes but that’s just me. As long as the design doesn’t increase the acoustic noise produced during operation, all should be fine.

Here we have those ribbon cables they keep talking about. Looking at the main ATX cable, I’ve got to side with Wolf. Multiple ribbons in one cable to me just doesn’t look good, and they never lay down evenly, ones always got to bulge out a little more. The 4+4 pin CPU cable looks just fine and should be plenty long enough for even the tallest cases.

Using a single ribbon just allows for better cable routing. Above left, we have the PCI-e cable equipped with a pair of 6+2 connectors. On the right, we have one of the SATA cables.

Here we have the SATA/5.25″ cable on the left and the SATA/5.25″/3.5″ cable on the right. I’ve gotten to the point these days, that I prefer that the 3.5″ connector be put on a short adapter cable. Just makes things so much simpler.

|

Hydro PTM 750W – Cabling |

|||

|

Type of Cable |

Length from PSU |

AWG |

|

|

Modular Cables |

|||

|

20+4 pin ATX connector |

600 mm |

18/22 |

|

|

4+4 pin CPU |

700 mm |

18 |

|

|

4+4 pin CPU |

700 mm |

||

|

6+2 pin PCI-e, 6+2 pin PCI-e |

500+150 mm |

||

|

6+2 pin PCI-e, 6+2 pin PCI-e |

500+150 mm |

||

|

6+2 pin PCI-e, 6+2 pin PCI-e |

500+150 mm |

||

|

SATA+SATA+SATA+SATA |

500+155+155+155 mm |

||

|

SATA+SATA+SATA+SATA |

500+155+155+155 mm |

||

|

SATA+SATA+5.25″+5.25″ |

500+155+155+100 mm |

||

|

SATA+SATA+5.25″+5.25″ |

500+155+155+100 mm |

||

|

SATA+SATA+5.25″+3.5″ |

500+155+155+155 mm |

18/22 |

|

|

Unit Dimensions (L x W x H) |

|||

|

170 mm x 150 mm x 86 mm |

|||

There you have it, we’re all wired up. Now let’s get on with the testing.

Test Setup

Today we will be using a SunMoon SM-5500ATE for loading the FSP Hydro PTM 750W. I’ll also be using a Rek PF9901 power meter, a USB Instruments Stingray oscilloscope, a dual probe thermometer, a Fluke digital multimeter, a CyberTech digital tachometer, and my custom hot box.

Let’s get the standby tests out of the way.

Load Tests

|

Hydro PTM 750W – STANDBY Load Tests |

||||

|

Test # |

+5VSB |

DC Watts/ |

Eff. |

P.F. |

|

Load Tests |

||||

|

1 |

0.5 A |

2.54 W/ |

85.95 % |

0.307 |

|

5.071 V |

||||

|

2 |

1.25 A |

6.30 W/ |

86.05 % |

0.437 |

|

5.039 V |

||||

|

3 |

2.5 A |

12.50 W/ |

84.46 % |

0.506 |

|

5.000 V |

||||

Starting the standby tests off, we see that the load regulation comes in with a very respectable 1.42%.

Moving over to the efficiency side of the table, we see even better results. We are giving Wolf’s “most efficient” unit a run for its money.

Cold Load Tests

|

Hydro PTM 750W – Cold Load Tests |

||||||||||

|

Test # |

+3.3V |

+5V |

+12V |

+5VSB |

DC W/ |

AC |

Eff. |

P.F. |

Int / |

RPM |

|

Progressive Load Tests |

||||||||||

|

1 |

1.1 A |

1.1 A |

5.3 A |

0.25 A |

74.28 W/ |

123.9 V |

86.47 % |

0.986 |

19°C / |

824.5 |

|

3.362 V |

5.061 V |

12.03 V |

5.074 V |

|||||||

|

2 |

2.3 A |

2.3 A |

10.7 A |

0.5 A |

150.54 W/ |

123.5 V |

90.25 % |

0.995 |

19°C / |

825.5 |

|

3.358 V |

5.054 V |

12.03 V |

5.057 V |

|||||||

|

3 |

3.4 A |

3.4 A |

16.0 A |

0.75 A |

224.71 W/ |

122.6 V |

91.68 % |

0.997 |

19°C / |

827.2 |

|

3.355 V |

5.047 V |

12.02 V |

5.049 V |

|||||||

|

4 |

5.7 A |

5.7 A |

26.7 A |

1.25 A |

374.99 W/ |

123.3 V |

92.43 % |

1.000 |

20°C / |

828.6 |

|

3.347 V |

5.033 V |

12.02 V |

5.035 V |

|||||||

|

5 |

8.0 A |

8.0 A |

37.4 A |

1.75 A |

525.19 W/ |

122.7 V |

91.82 % |

1.000 |

20°C / |

833.3 |

|

3.340 V |

5.019 V |

12.02 V |

5.013 V |

|||||||

|

6 |

9.2 A |

9.2 A |

42.8 A |

2.00 A |

601.25 W/ |

121.9 V |

91.28 % |

1.000 |

21°C / |

835.0 |

|

3.336 V |

5.011 V |

12.02 V |

4.999 V |

|||||||

|

7 |

10.4 A |

10.4 A |

48.1 A |

2.25 A |

675.96 W/ |

122.7 V |

90.84 % |

1.000 |

21°C / |

837.2 |

|

3.332 V |

5.004 V |

12.02 V |

4.988 V |

|||||||

|

8 |

11.5 A |

11.5 A |

53.5 A |

2.50 A |

750.99 W/ |

122.6 V |

90.25 % |

1.000 |

22°C / |

1040.1 |

|

3.329 V |

4.997 V |

12.02 V |

4.976 V |

|||||||

Crossload Tests

|

Crossload Tests |

||||||||||

|

CL1 |

14.4 A |

14.4 A |

0.0 A |

0.0 A |

120.18 W/ |

122.9 V |

85.84 % |

0.993 |

20°C / |

830.0 |

|

3.343 V |

5.003 V |

12.03 V |

5.077 V |

|||||||

|

CL2 |

0.0 A |

0.0 A |

62.5 A |

0.0 A |

751.09 W/ |

122.5 V |

90.66 % |

1.000 |

22°C / |

930.2 |

|

3.346 V |

5.047 V |

12.02 V |

5.071 V |

|||||||

Starting off with the load regulation. On the +3.3V rail, we have 1.0%. The +5V rail comes in a tad looser at 1.28%. The +12V rail brings in the tightest numbers with 0.08%. The +5VSB brings up the rear with 2.02%. Overall we’re looking pretty good so far.

With the Hydro PTM being 80PLUS Platinum rated means we should see 90% efficiency @ 20% load, 92% efficiency @ 50% load, and 89% efficiency @ 100% load. At 20% load in Test 2, we achieved 90.25%. At 50% load in Test 4, we achieved 92.43%. At full load in Test 8, we come in at 90.25%. So we did manage to achieve platinum efficiency, but we didn’t leave much room for error.

We can see that the Hydro PTM managed to stay pretty cool during the cold testing hitting a maximum of 26°C.

If you recall, our little graph showed that the fan should run at roughly 700RPM and start ramping up with a maximum of roughly 1200RPM. As you can see, we carried roughly 830RPM on average with a peak of 1040.1RPM during the full load test.

Overshoot Transient Tests

|

Hydro PTM 750W – Overshoot Transient Tests |

|||

|

VSB On |

VSB to 100%, 12V |

Off to 100%, 12V |

|

Well, we start off looking good with the first test. However, both shots on the 12V side are definitely not what you would call smooth and continuous. That’s going to cost them a little when it comes time to score this thing.

Let’s get the second round of testing going.

Hot Load Tests

|

Hydro PTM 750W – Hot Load Tests |

||||||||||

|

Test # |

+3.3V |

+5V |

+12V |

+5VSB |

DC W/ |

AC |

Eff. |

P.F. |

Int / |

RPM |

|

Progressive Load Tests |

||||||||||

|

1 |

1.1 A |

1.1 A |

5.3 A |

0.25 A |

74.29 W/ |

120.5 V |

86.79 % |

0.984 |

24°C / |

864.2 |

|

3.362 V |

5.061 V |

12.03 V |

5.073 V |

|||||||

|

2 |

2.3 A |

2.3 A |

10.7 A |

0.5 A |

150.60 W/ |

123.4 V |

90.50 % |

0.995 |

26°C / |

866.8 |

|

3.359 V |

5.054 V |

12.03 V |

5.055 V |

|||||||

|

3 |

3.4 A |

3.4 A |

16.0 A |

0.75 A |

224.80 W/ |

123.0 V |

92.24 % |

0.997 |

27°C / |

870.6 |

|

3.355 V |

5.047 V |

12.03 V |

5.057 V |

|||||||

|

4 |

5.7 A |

5.7 A |

26.7 A |

1.25 A |

375.12 W/ |

123.1 V |

92.48 % |

0.998 |

30°C / |

877.6 |

|

3.347 V |

5.033 V |

12.03 V |

5.026 V |

|||||||

|

5 |

8.0 A |

8.0 A |

37.4 A |

1.75 A |

525.19 W/ |

123.1 V |

91.75 % |

0.998 |

32°C / |

885.1 |

|

3.340 V |

5.019 V |

12.02 V |

5.010 V |

|||||||

|

6 |

9.2 A |

9.2 A |

42.8 A |

2.00 A |

601.47 W/ |

122.8 V |

91.28 % |

1.000 |

35°C / |

888.2 |

|

3.337 V |

5.011 V |

12.03 V |

4.997 V |

|||||||

|

7 |

10.4 A |

10.4 A |

48.1 A |

2.25 A |

676.19 W/ |

121.4 V |

90.64 % |

0.998 |

36°C / |

890.3 |

|

3.333 V |

5.003 V |

12.02 V |

4.982 V |

|||||||

|

8 |

11.5 A |

11.5 A |

53.5 A |

2.50 A |

751.36 W/ |

120.9 V |

89.94 % |

1.000 |

38°C / |

1125.1 |

|

3.329 V |

4.995 V |

12.02 V |

4.971 V |

|||||||

Crossload Tests

|

Crossload Tests |

||||||||||

|

CL1 |

14.4 A |

14.4 A |

0.0 A |

0.0 A |

120.17 W/ |

122.0 V |

85.96 % |

0.993 |

23°C / |

870.4 |

|

3.342 V |

5.003 V |

12.02 V |

5.078 V |

|||||||

|

CL2 |

0.0 A |

0.0 A |

62.5 A |

0.0 A |

751.41 W/ |

120.7 V |

90.48 % |

1.000 |

34°C / |

878.8 |

|

3.346 V |

5.047 V |

12.02 V |

5.070 V |

|||||||

Ok, we’re starting with the load regulation first. On the +3.3V rail, we end up with the same 1.0% as we had in cold testing. On the +5V rail, we have a slight increase to 1.32%. The +12V rail stays unchanged at 0.08%. Lastly, we have the +5VSB rail increasing to 2.14%.

On the efficiency side of the scale, we need to achieve 90%, 92%, and 89% at 20%, 50%, and 100% loads. At the 20% mark in Test 2, we hit 90.5%. At 50% load in Test 4, we hit 92.48%. Lastly, at 100% load in Test 8, we hit 89.94%. We have a clean pass for 80PLUS Platinum certification.

Utilizing a hot-box setup as we do, it becomes a challenge trying to heat up some of these very efficient power supplies. This unit, for example, managed to hit 22°C in/26°C ex in the cold tests and 38°C in/36°C ex here in the hot tests.

Looking at the fans RPMs, we can see the increased heat did cause the fan to spin a little more.

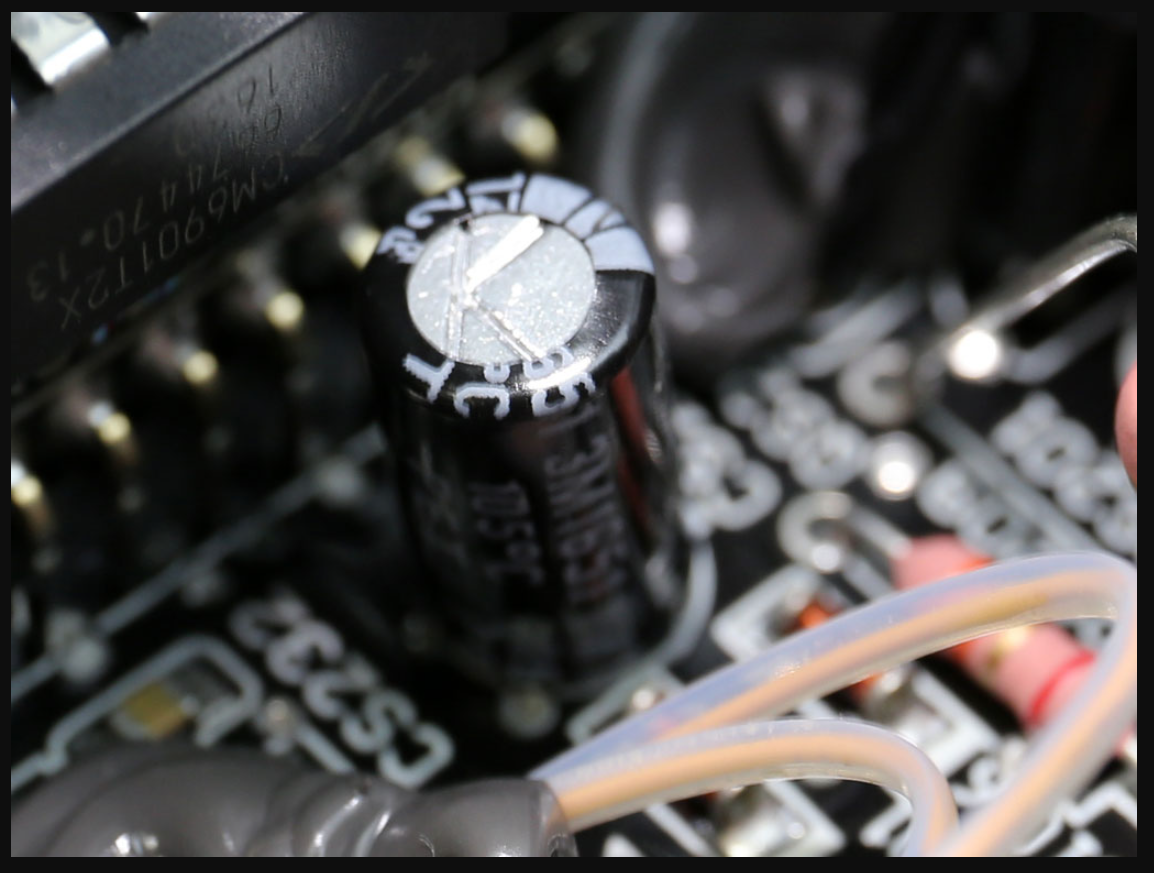

Internal components of the power supply

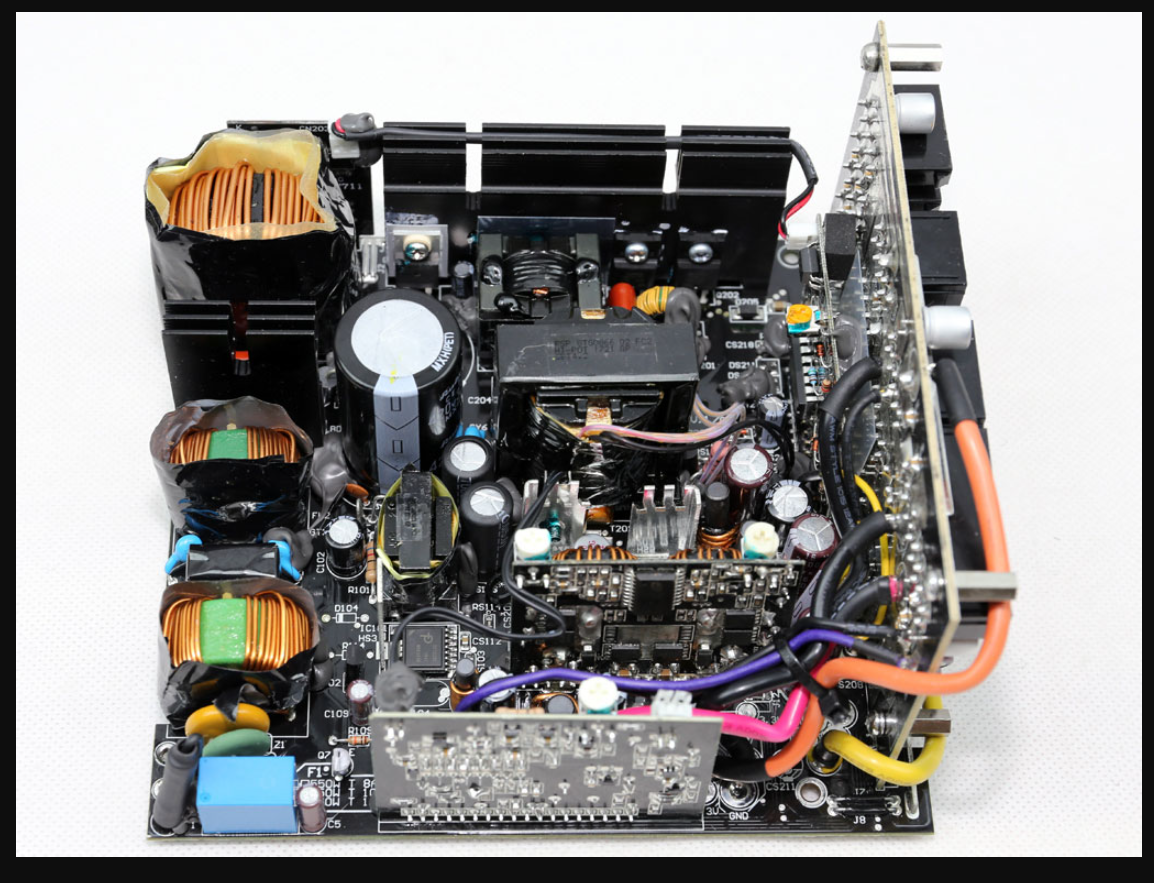

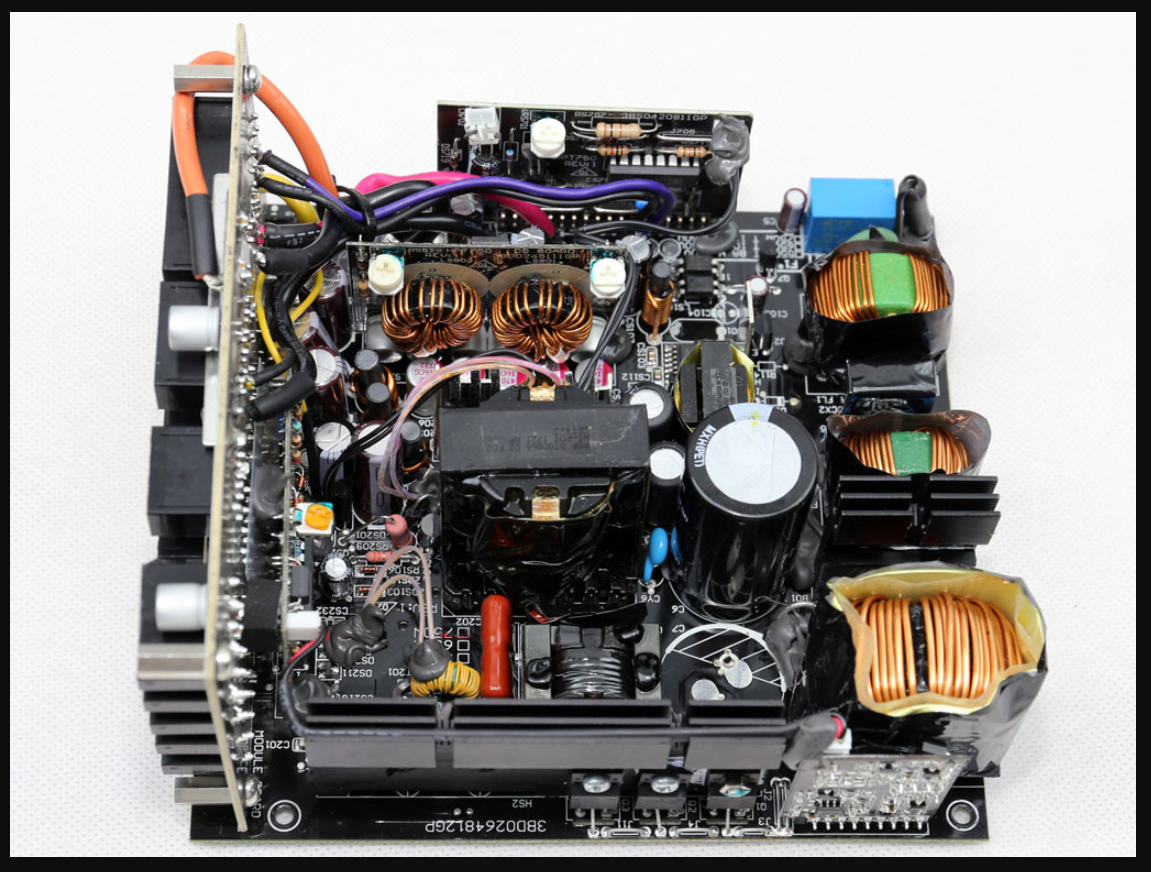

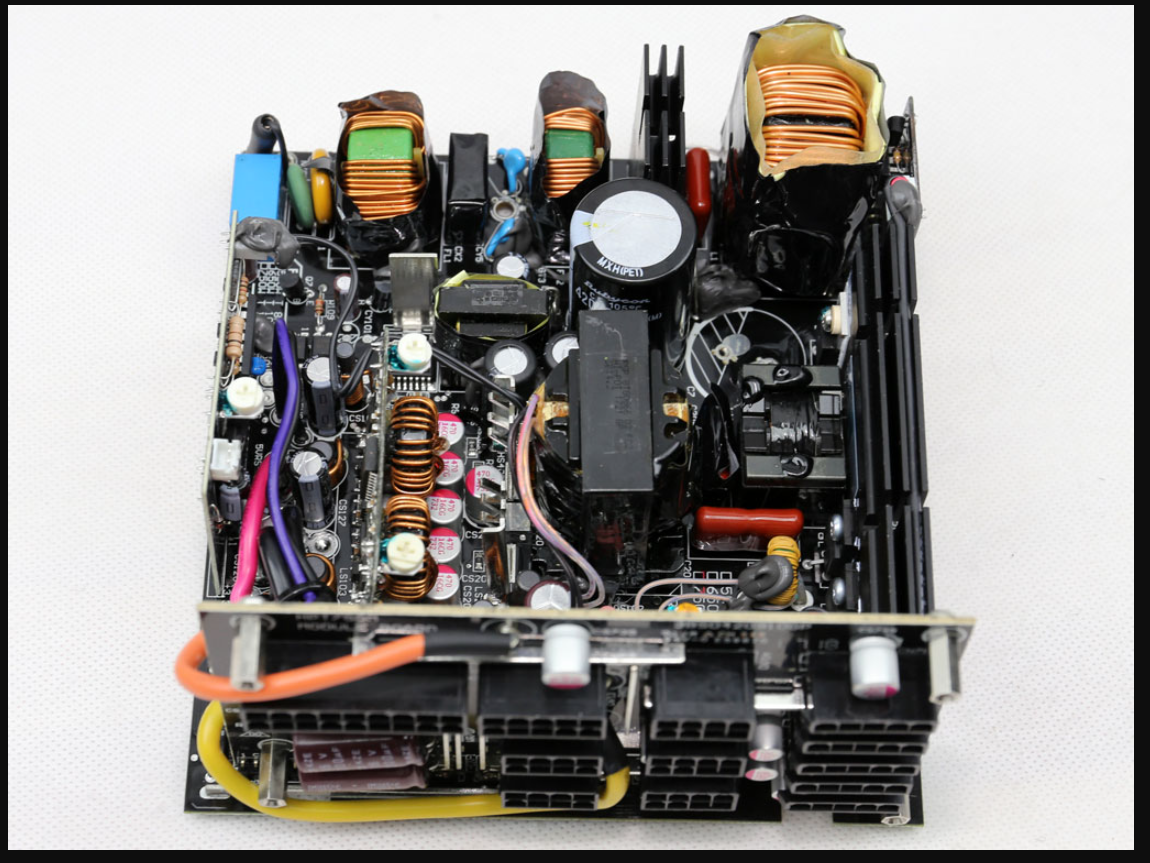

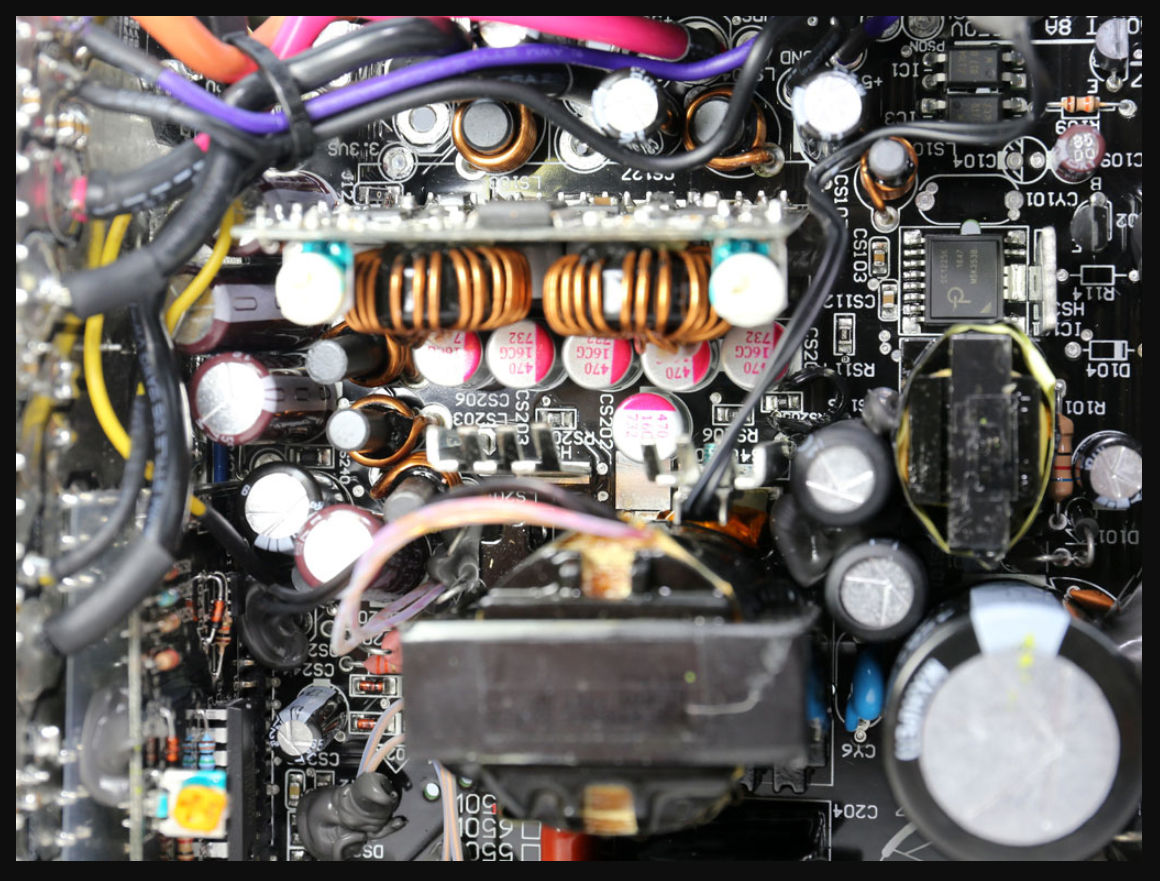

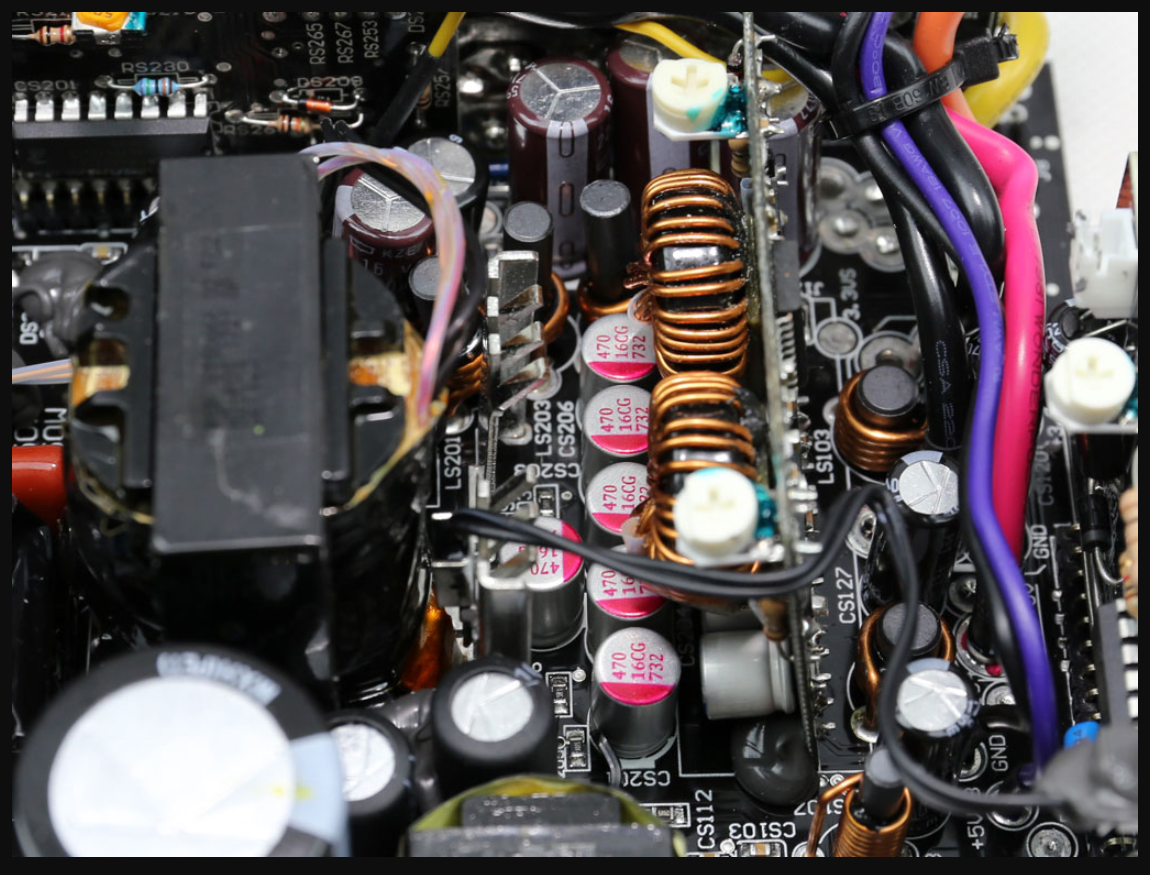

The FSP Hydro PTM 750W utilizes an LLC half bridge topology with DC-DC for the minor rails.

Upon opening the case we find the Protechnic Electric MGA 13512XF-A25 FDB fan with the following specs. It’s rated at 12V, 0.38A, 4.56W, 115.8CFM, and has a max RPM rating of 2300.

Here’s the Hydro PTM with it’s top off. With everything spaced out fairly well, there shouldn’t be any cooling issues.

Here we can take a tour around the unit, once we have the main PCB pulled from the casing.

On the left, we have the bridge rectifier, a GBJ2506. On the right, we have our first daughterboard which houses the PFC controller, an Infineon 2PCS02.

Here we have one of the two primary capacitors removed, a Rubycon 420V330µF MXH series rated at 105°.

Located on the outer part of the heatsink on the primary side is our three Toshiba TK20A60W MOSFETs for the APFC. On the back side of the heatsink, we have a CREE C3D06060 boost diode that’s tucked in behind primary cap we took out.

Located on a daughterboard between the APFC parts and the rear of the modular interface PCB we find the LLC resonant controller, a Champion CM6901.

Throughout the Hydro PTM we find several Chemi-Con and Rubycon electrolytic capacitors.

Just in front of the DC-DC PCB daughterboard, we have two small heatsinks that are used to aid in cooling the +12V MOSFETs which are located on the solder side of the main PCB.

Directly in front of the DC-DC PCB, we find several Teapo polymer capacitors. The DC-DC board itself is populated with FP and CapXon polymer capacitors.

Just behind the DC-DC PCB, we have another daughterboard that houses the protections IC, a SiTI PS223.

The standby PWM controller is a Power Integrations SC1225K, that is located close to the DC-DC PCB.

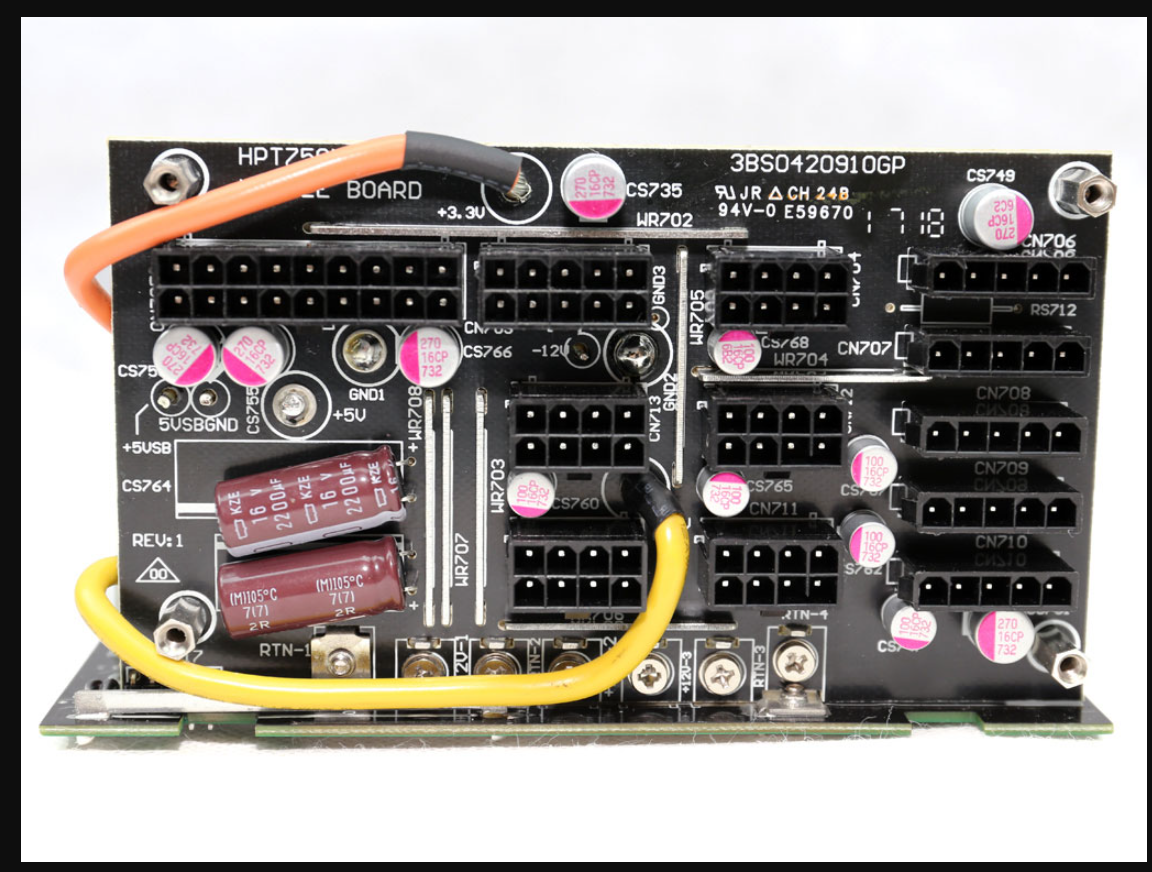

Our modular interface PCB is populated with a few Chemi-Con electrolytic caps, and several Toshiba polymer caps. Soldering quality doesn’t look to bad.

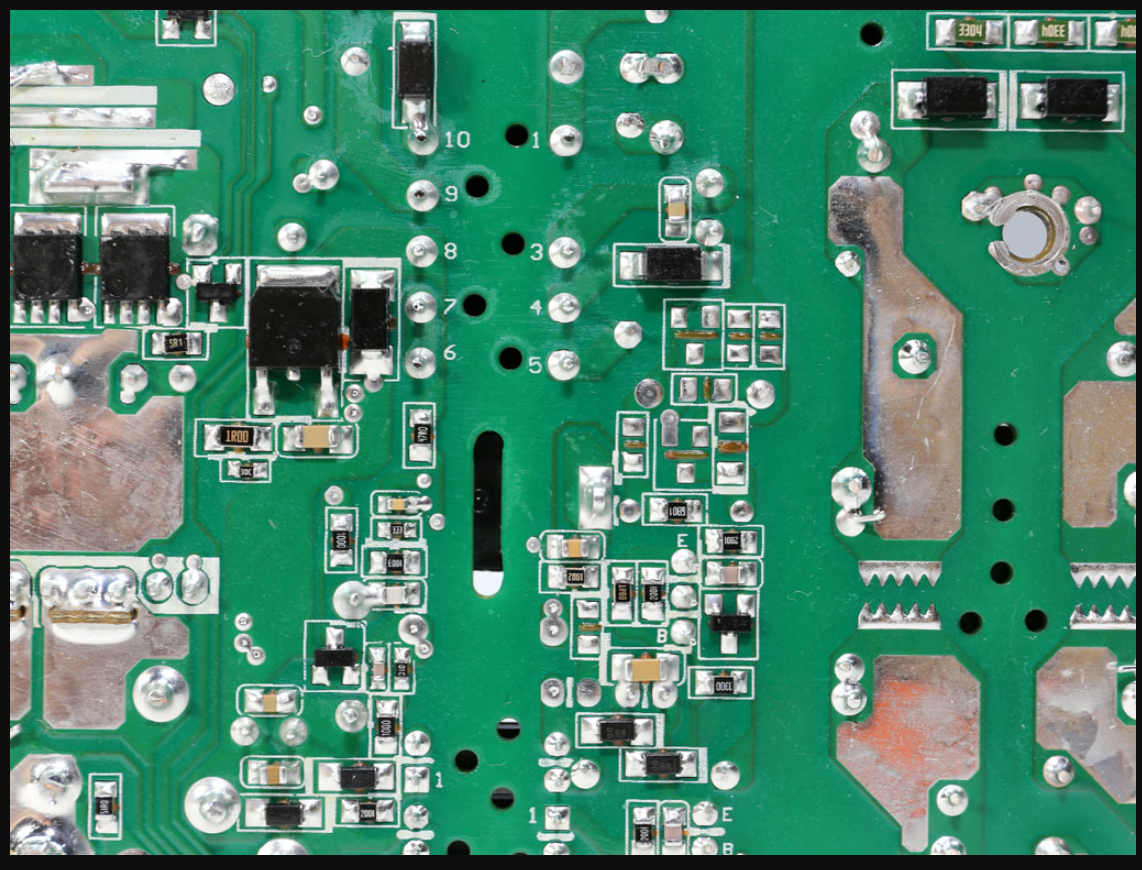

Looking at the soldering side of the main PCB, we see that FSP has done a pretty good job. However, we do have some infractions when it comes to long component leads.

On the left, we have the +12V MOSFETs, four Toshiba TPHR8504PL’s, and on the right is an International Rectifier IRFR1018E for the +5VSB rail.

Conclusion

Performance (40% of the final score) – Our standby tests provided great results with no deductions. During the transient tests, we did have a couple of +12V hiccups in the S&C section costing the Hydro PTM a half-point deduction. In the voltage regulation department, we had some pretty decent results with all close to the 1% +/-, which leaves me pulling another half-point.

We had no issues hitting the 80PLUS Platinum figures, so no deductions there. Ripple suppression on the Hydro PTM was very good as well with single digits on the minors and only 22 mV on the major. That leave’s us with an overall performance score of 9.

Functionality (20% of the final score) – With this unit being in the higher end bracket, I expected to see it come with a few goodies whether it be extra Velcro strips, Zip ties, or something.

They do give you an option of deciding if you want to keep the blue stickers or replace them with the red or green ones. That’s a nice adder, but not enough to compensate for the lack of extras so we’re pulling a half-point. I am also not fond of the single piece of paper folded up being considered a user manual, which means another half-point deduction.

The Hydro PTM is fully modular so no deductions there. I do like the flat cables on occasion, but I’m not a fan of them on the 20+4 ATX cable. I think FSP did well with the connector count for the most part. However, I still like having at least one cable dedicated to 5.25″ connectors just for accessories which means another half-point deduction.

Although I’m not dinging FSP for it, the misleading “0dB Zero Noise” label on the box does need to be removed. This leaves us with a functionality total of 8.5.

Value (20% of the final score) – With this review coming in a bit late (all my fault), I feel I’ve still got to give it its score based on the current pricing just to keep things fair.

Right now the FSP Hydro PTM 750W is listed for $134.99 US @ NewEgg. We also see the Seasonic FOCUS Plus 750W Platinum @ $119.57, while units like the Corsair HX750i & the Seasonic PRIME Ultra 750W Plat coming around $145.00. We also see a few topping the $160 ish mark like the Rosewill TACHYON 750.

This moves the FSP towards the lower end of the scale, which puts us at an 8.5 here.

Build Quality (20% of the final score) – When it comes to build quality, FSP has always done pretty good with today being no exception. The only thing I’m going to ding them on today is the long component leads I found on the solder side of the main PCB.

So that puts us at 9.5.

|

Hydro PTM 750W – Scoring |

|

|

Performance |

9 |

|

Functionality |

8.5 |

|

Value |

8.5 |

|

Build Quality |

9.5 |

|

Total Score |

8.9 |

Overall, the Hydro PTM 750W gave us everything that FSP said it would. We have a fully modular, platinum certified, single +12V rail, quality components, which makes this a competitive power supply. It’s hanging in there with the best of them. With some tweaks here and there it could easily improve its position in the market.

The GOOD

- Fully Modular

- Single +12V Rail

- Platinum Efficiency

- Good Build Quality

- Good Load Regulation

- 135 MM FDB Fan

- 10 Year Warranty

The BAD

- N0 Zero dB Noise